The SZGH-650 is a high-performance mini CNC milling machine, a versatile solution tailored for metalworking applications. Paired with the advanced SZGH-CNC1000Mic-3 CNC controller, this mini CNC milling machine delivers precise and efficient operation, making it an indispensable addition to any modern CNC machine tool collection for metalworking shops, whether small-batch production or specialized part machining.

In terms of workpiece compatibility, this mini CNC milling machine (SZGH-650) excels at processing a wide range of common metal materials, including copper, iron, aluminum, and stainless steel—materials widely used in industries such as automotive, aerospace, electronics, and mechanical manufacturing. The SZGH-650 machine mill can process workpieces up to 600mm x 500mm, a size range that covers a wide range of critical components, from small precision parts like electronic connectors to medium-sized structural components in mechanical assemblies. This eliminates the need for multiple CNC machines to process different material types and sizes, streamlining production processes for shops of all sizes who rely on efficient micro CNC milling solutions.

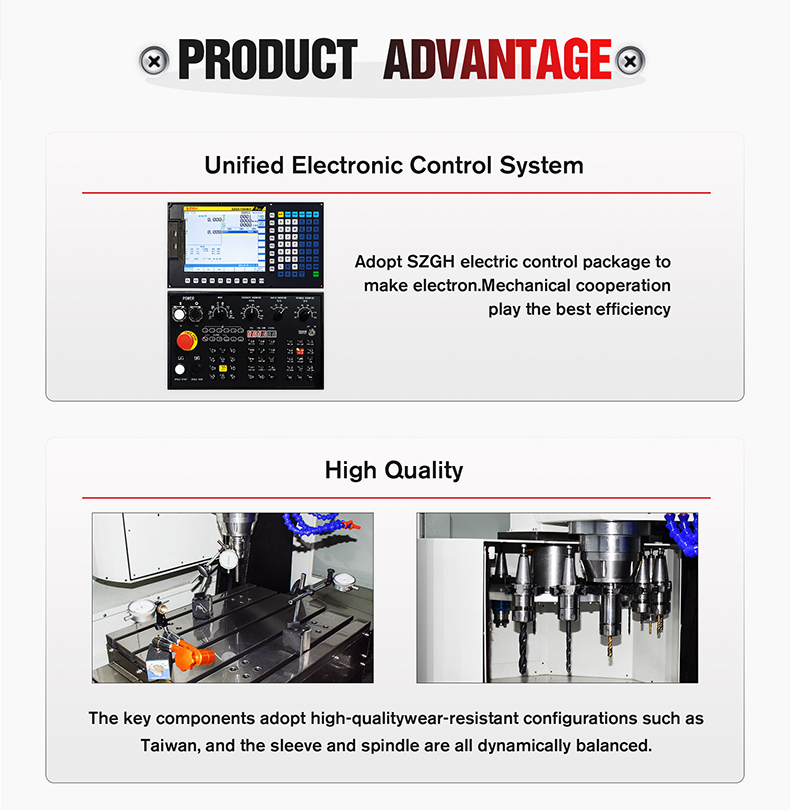

In terms of operational compatibility, the SZGH-650 micro CNC mill is designed to seamlessly integrate with existing general-purpose machining centers—another key advantage that distinguishes it from standard CNC machines. This means that operators familiar with standard CNC machine operations can quickly become familiar with the micro CNC mill without extensive retraining, shortening the learning curve and minimizing operational errors. The consistent operating logic of this small CNC mill ensures a smooth transition, from programming to setup and daily operation, allowing shops to maintain productivity even when integrating new CNC machines into their workflows.

Functionally, this small CNC milling machine (SZGH-650) is a true all-rounder, supporting a range of metalworking tasks critical to end-to-end part production. As a specialized CNC machine, it excels in drilling, creating precise holes to tight tolerances to meet the stringent requirements of precision engineering. Tapping, another key capability of this small CNC milling machine, allows for the creation of internal threads with high precision—critical for parts assembled with fasteners.

Milling operations, a core function of any high-quality CNC machine, are performed with exceptional stability on the SZGH-650: Whether face milling, perimeter milling, or contour milling, it ensures smooth surface finishes and precise part geometry. Furthermore, this mini CNC milling machine supports engraving, making it ideal for adding detailed markings, logos, or complex patterns to metal workpieces. This enhances product value in industries where branding or part identification is crucial, further solidifying its position as an ideal multi-functional CNC machine.

The SZGH-650 mini CNC milling machine is particularly well-suited for machining stainless steel parts—a material known for its high hardness and toughness, which poses a challenge to less robust CNC machines. This mini CNC milling machine can handle tapping operations up to 30 mm and drilling operations

| Project | Unit | Standard value | Max value | |

| Processing capacity | Maximum drilling diameter | mm | Aluminum φ35/ Steel φ30 | Aluminum φ40/ Steel 35 |

| Max. Tapping Diameter | mm | Aluminum m25/ Steel m18 | Aluminum m25/ Steel m20 | |

Max. milling cutter diameter | mm | φ60 | φ100 | |

| Max. Spindle speed | rpm | 6000 | Optional 24,000-rpm motorized spindle | |

| Handle Type | - | BT40 | Optional BT30 | |

| Magazine capacity | - | 10-station servo tool magazine | 12 station tool magazine | |

| Repeatability | mm | 0.01 | - | |

| Surface engraving accuracy | mm | ±0.02 | optional ±0.01 | |

| workbench | Distance from table surface to spindle end | mm | Minimum 150 Maximum 450 | - |

| Effective stroke of working surface | mm | 600*500 | - | |

| Travels | X-axis effective travel | mm | 500 | - |

| Y-axis effective travel | mm | 600 | - | |

| Z-axis effective travel | mm | 300 | - | |

| Feed | X-axis rapid traverse | m/min | 25 | 30 |

| Y-axis rapid traverse | m/min | 25 | 30 | |

| Z-axis rapid traverse | m/min | 20 | 25 | |

| Various cutting suggested speeds | m/min | 1000 | - | |

| Spindle | Max.Spindle Speed | rpm | 6000 | Optional 24000electric spindle |

| Spindle Motor Power | kW | 3.7 | Optional 5.5kw | |

| Spindle type | - | mechanical spindle | Optional electric spindle | |

| Spindle taper | - | BT40 | Optional BT30 | |

| Dimensions | Dimensions | mm | 1650*1800*2450 | - |

| Total Weight | kg | 2900 | - | |

| Machine tool specifications and component items | Specification | Standard | Optional | |

| Part Specifications | Screw | 32mm | Taiwan precision p grade | - |

| Guide rail | 30mm | Taiwan Precision C3 Grade | - | |

| Spindle | BT40 | Yashu self-made | other | |

| CNC Control | - | SZGH | SZGH | |

| Feed servo | X.Y1.2kw&1.5kW | SZGH | SZGH | |

| Spindle servo motor | 3.7kW | SZGH | SZGH | |

| Machine specifications | Tool magazine | 10/12 handle | SZGH | - |

| Base form | 1200kg | Heavy-duty anti-deformation patented base | - | |

Why Choose SZGHTECH:

1.SZGHTECH has been specialized in producing automation equipment for more than ten years, including CNC milling and lathe machine, servo motor and controller...

2.SZGHTECH milling machine provide the most complete services.We have very high-quality products and very professional R&D and technical teams.

3.Language Spoken :our milling machine support English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean, Italian, and so on.

4.SZGHTECH's mission is: quality first, customer first. Welcome to consult SZGHTECH's CNC milling machine from all over the world. We are online 24 hours a day to serve you!