What does it take to produce a CNC lathe?

1. Lathe bed material: Cast iron, such as gray cast iron, is typically used because of its excellent rigidity, shock absorption, and wear resistance. Cast iron can withstand high cutting forces, ensuring machine accuracy and stability.

2. Lathe spindle material: We generally use high-strength, high-hardness, high-quality steel to ensure spindle rotational accuracy and rigidity, preventing deformation under high-speed rotation and cutting forces.

3. Lathe transmission component material: Transmission gears and other components are often made of high-quality steel. After carburizing and quenching, they have high surface hardness and excellent wear resistance, and good core toughness, allowing them to withstand heavy loads and impacts. Screws are typically made of alloy steel, requiring high wear resistance and high precision retention.

3. Lathe tool materials: Common materials include high-speed steel and cemented carbide. High-speed steel has high strength and toughness, making it suitable for machining parts with complex shapes. Cemented carbide has higher hardness, wear resistance, and heat resistance, and is commonly used for high-speed cutting and machining hard materials.

4. Materials for lathe electrical components: These include various wires, cables, contactors, relays, servo motors, and drives. Wires and cables require excellent conductivity and insulation, while servo motors and other components require high precision and fast response speed.

5. Other materials required for CNC lathe production: For example, the material used to manufacture machine guide rails requires excellent wear resistance and a low coefficient of friction. Steel-lined or plastic-coated guide rails are acceptable. Machine tool protective covers are typically made of stainless steel or cold-rolled steel for excellent corrosion resistance and strength. Seals are typically made of materials such as rubber and polyurethane to ensure a tight seal and prevent leakage of lub

The steps involved in producing a CNC lathe are as follows:

1. Design Phase:

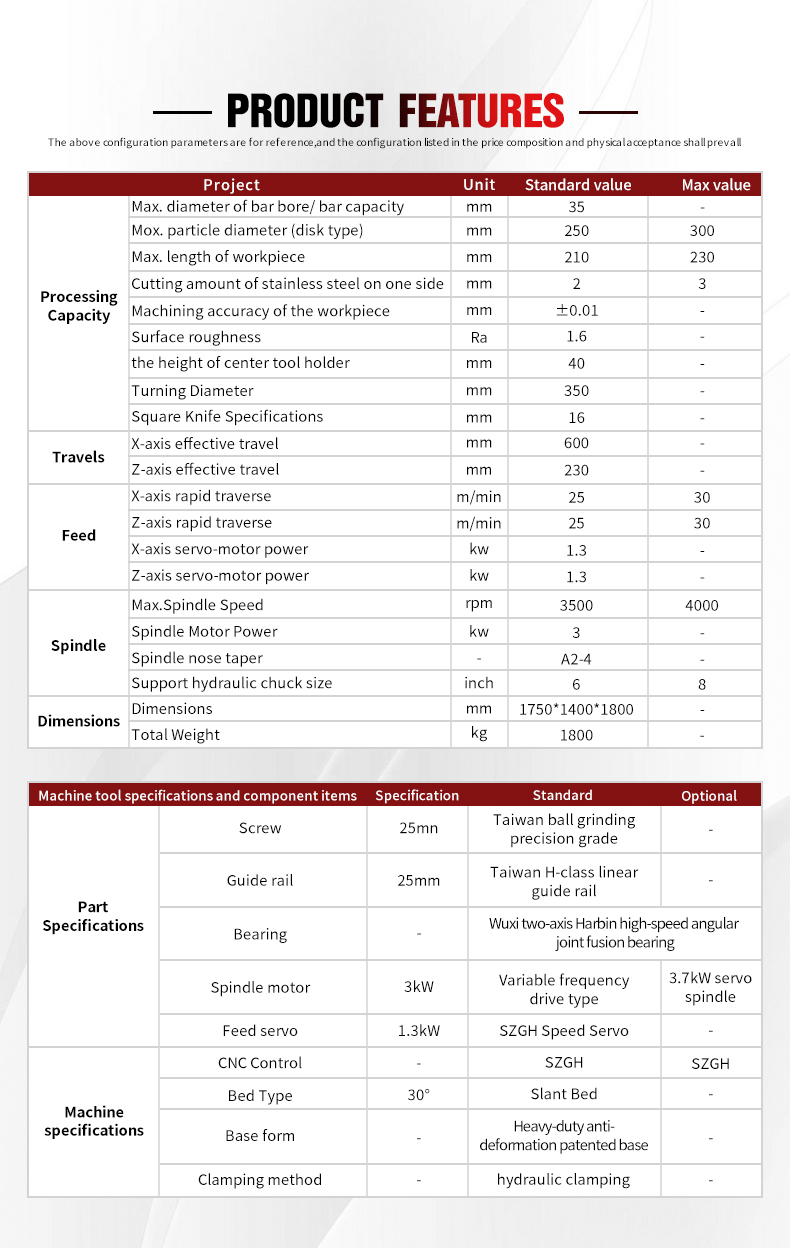

1) Requirements Analysis: Based on market demand and customer requirements, the performance indicators and functional characteristics of the CNC lathe are determined, such as machining accuracy, maximum machining dimensions, spindle speed range, and feed rate.

2) CNC Lathe Technical Design: The design team develops a detailed design plan, including the machine tool's structural design, such as the structure and dimensions of the bed, spindle box, and tool holder; and electrical system design, such as the selection of the CNC system and the design of the electrical control circuit. Relevant calculations and simulation analysis are then performed to ensure the feasibility of the design.

2. CNC Lathe Manufacturing:

1) CNC Lathe Component Processing: Advanced CNC equipment, such as CNC lathes, milling machines, and grinders, is used to precisely manufacture each component according to the design drawings. For example, CNC lathes are used to machine rotating parts such as spindles and lead screws, while milling machines are used to machine complex shapes such as housings and bed frames.

2) Lathe CNC Precision Assurance: During the machining process, high-precision machining techniques and measurement methods are employed to ensure component quality and accuracy. For example, grinding and polishing are used to improve component surface quality, and equipment such as coordinate measuring machines are used to inspect component dimensions and geometric tolerances.

3. Lathe CNC Assembly and Commissioning:

1) Lathe CNC Assembly Process: The machined components are assembled into the machine tool structure in the correct order and method. Components are assembled first, such as the spindle, bearings, and gears, into the spindle box. The individual components are then assembled into the complete machine. Component commissioning and adjustments are performed simultaneously, such as adjusting the spindle's radial and axial runout, and the guideway's straightness and parallelism.

2) Lathe CNC Functional Testing: After assembly, the machine tool undergoes various functional and performance tests, including spindle speed testing, feed system accuracy testing, and tool change accuracy testing, to ensure proper functioning of the machine tool.

4. CNC Lathe Quality Inspection:

1) Full-Process CNC Lathe Inspection: From raw material inspection to component processing quality inspection, and finally to complete machine inspection, strict quality control is required. For example, physical and chemical property testing of raw materials, spot checks of component dimensions and surface quality, and visual inspection, precision testing, and performance testing of the complete machine are performed.

2) Finished CNC Lathe Inspection: The final CNC lathe undergoes a comprehensive inspection, including whether its appearance quality meets requirements and whether its performance indicators meet design standards. Actual machining tests are conducted on typical parts to check the machining accuracy and surface quality to verify the overall performance of the machine.

5. Shipping and After-Sales Service:

1) Packaging and Shipping: Qualified CNC lathes are packaged in standardized packaging to prevent damage during transportation. After completing freight procedures, they are shipped to the customer's designated location.

2) After-Sales Support: Customers are provided with installation guidance, operator training, repair and maintenance services, and other after-sales services to ensure proper use and maintenance of the machine, ensuring proper operation and improving customer satisfaction.